We got our coldest weather a bit early this year with it getting into the 30's since Thanksgiving. So I've been running the little heater and spending quite a bit of time in the train room and getting a lot done at the eastern end of the layout.

As mentioned in the previous post, the completion of the east end return loop means that the entire main line is now done. This first photo shows the return loop with the pair of stub end staging tracks in the middle. This area is directly above the Weso section of the layout and is at 68 inches from the floor. This happens to be my height and I can easily reach this with a short step stool. Trains that come into those stub end staging tracks will need to have there engines and caboose swapped by hand.

This next photo shows the entry into this area which is at the top of the helix. The arrangement of the turnouts allows for a train to enter or leave the staging tracks from either helix track. In practice they will mostly enter from the eastbound WP/UP line and depart from the westbound SP line. I had a box of used Peco turnouts that had been given to me years ago and selected 4 that appeared to be in the best condition. So far they are working well but all of these are just track nailed down so future repair or replacement is possible if any problems occur.

The short wall that is visible behind the Tortoise motors is to allow mounting of circuits and connections related to this area. In this next photo some of this is visible including the Digitrax DS64 that controls the turnout motors. Wiring is still in progress at this point. The circuit board shown connected to the DS64 outputs is a test board I made up to assist with programming. The Yellow LED's indicate a closed turnout position and the red ones indicate a thrown position.

For now at least this group of turnouts will be controlled by this control panel which is currently mounted on a scrap of hard board which is attached to the helix. Eventually the fascia will be extended from the left and this panel will be mounted to that.

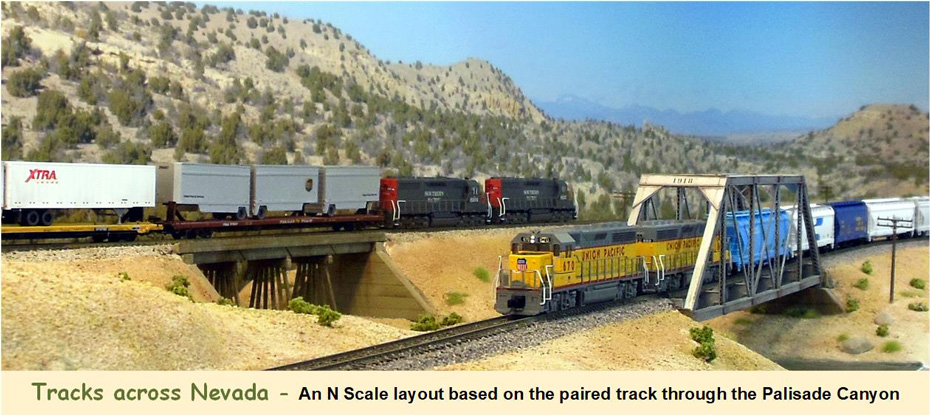

Again this winter I am posting in the Trainboard.com annual winter layout party thread. There have not been any train shows again this year for me to exhibit my Ntrak modules or AsiaNrail modules. Two events are scheduled next year in April and June but until then I'll just keep working on this layout.