Most railroad have had a practice of painting the handrails of their locomotives and cabooses in a contrasting color as a safety measure. Sometimes this practice is extended to the edges of the steps. SP and UP used white Many of the older Kato and Kato made Atlas locomotives I have on the layout did not come with painted handrails.

On these models the handrails and walkways are a separate assembly that is made of a durable and smooth plastic a little different than the other components. It is easier to paint the handrails with this assembly removed.

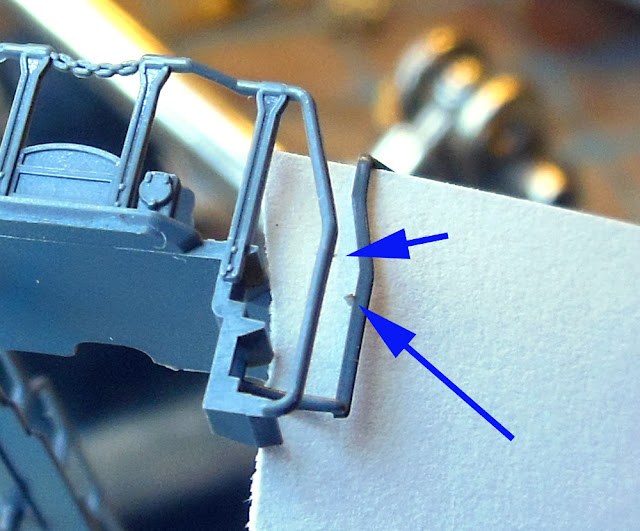

On some of these models it is not uncommon to find a bit of flash on the handrails. Referring to the photo below, it is not very noticeable in the basic gray color so I placed a bit of white paper behind it. Once the handrails are painted, the flash is more noticeable so it's best to remove it before painting. These small flashes can be removed with a sharp Exacto blade. After this I give the assembly a good washing with warm water and dish soap using an old toothbrush and then letting it dry before painting.

That durable and smooth plastic of the handrails does not stick to paint very well. Over the years I have tried several brands and types of paint and ended up having the best results from Testors Practa Racing Finish Enamel. This is made for R/C car bodies which are made of a flexible plastic. Even using this paint some of the paint would flake off the handrails over time with handling the models.

Recently I had read about some modelers using spray adhesion promoters to get better results when painting such plastics. Not finding any product like this at my local hardware store, I ordered the product shown below from Amazon. It is clear so masking of the handrail assembly was not necessary.

After some practice I learned the trick to using this product is to spray the hand rails at one end then let it dry to the touch, about 3-4 minutes. Then paint the hand rails with the top coat within 10 minutes.

I have now done 5 locomotives this way with some of those shown in the photo below. This technique is getting me the best results yet. Over time I may go back and redo some of the others with this new technique.