With all the track connected from the staging yards through the helix and the Wesso sections of the layout, it was time to run some test trains trains. There is a limited amount of track east of Wesso junction but short trains can be run through the cross overs and return on a different line than they went up on.

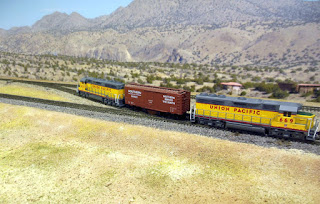

A pair of UP GP40's will start from the upper staging yard and a pair of SP SD35's will start from the lower staging yard. Each pair of locos has an Aztec track cleaning car in between them.

The SP train goes out first.

After climbing the helix the SP train arrives at Wesso and takes the cross overs from the SP line to the east bound paired track.

The UP train leaves next, starting it's climb up the helix. Because the upper level staging yard is one helix turn higher than the lower yard, this line has a one turn shorter run in the helix.

The UP train leaves the helix, passes through the small Winnemucca section which does not have scenery yet and approaches Wesso junction.

The UP train takes the cross over from the WP / UP line to the west bound paired track.

After passing through the cross overs, both trains arrive at the end of line both in terms of track and scenery just past the dry creek area. The UP train on the west bound track and the SP train on the east bound track.

After all of the points of the cross overs have been aligned, both trains begin moving west bound to return to the staging level. This time the UP train is entering the SP track to the lower level and the SP train is on the WP / UP track to the upper level.

On the trip down to the staging yard the UP train has the smaller radius and moves ahead of the SP train. The SP train however will leave the helix one turn before the UP train so they both end up in the staging yard at about the same time.

Here we are back at staging with the trains in opposite yards from where they started.

For the first time there is a connection between the two staging yards although it still requires a reverse move in one direction.

Monday, January 30, 2017

First trains reach Wesso from the staging yard

Sunday, January 22, 2017

Connecting M/E code 55 to Atlas code 80 track

The Wesso section has been bolted into place and the cork road bed installed on both line connecting the road bed between the helix and the Wesso section and it was time to make the track connections. The Atlas code 80 track from the helix would need to be connected to the Micro Engineering code 55 on the visible parts of the layout. There would also need to be a gap in the rails at the point were the helix and main line DCC power districts meet.

This was the first time I had connected Atlas code 80 track to Micro Engineering code 55 track. I started by making a plate from PC board material as I had done for track gaps in the staging yard, but this time I added a pair of .020 thick brass strips on one end.

The brass strips brought the code 55 rail up to the height of the code 80 rail. Then it was just a matter of aligning and soldering in place on the plate.

It is not pretty but it works. These will be out of view behind the sky board near the helix.

The isolation gaps between DCC power districts on both lines will be in the visible areas of the layout on the code 55 track. For that I am using a product called Gapmaster from the American Tie and Timber Company. These are 4 tie sections made from PC board material with a gap in the middle of each tie.

In the case of the WP line shown in this photo, I had two sections of M/E code 55 track where I used the Gapmaster instead of rail joiners. Then just a couple of passes with my razor saw to remove the PC board plating and complete the gap.

On the SP line I removed 4 ties and replaced them with the Gapmaster, then sawed through the rails.

I had already used the Gapmaster with very good results on the double crossovers at Wesso.

This photo shows one of those after the track was painted and ballast was applied. After the ties are painted they blend in with the rest of the ties.

This was the first time I had connected Atlas code 80 track to Micro Engineering code 55 track. I started by making a plate from PC board material as I had done for track gaps in the staging yard, but this time I added a pair of .020 thick brass strips on one end.

The brass strips brought the code 55 rail up to the height of the code 80 rail. Then it was just a matter of aligning and soldering in place on the plate.

It is not pretty but it works. These will be out of view behind the sky board near the helix.

The isolation gaps between DCC power districts on both lines will be in the visible areas of the layout on the code 55 track. For that I am using a product called Gapmaster from the American Tie and Timber Company. These are 4 tie sections made from PC board material with a gap in the middle of each tie.

In the case of the WP line shown in this photo, I had two sections of M/E code 55 track where I used the Gapmaster instead of rail joiners. Then just a couple of passes with my razor saw to remove the PC board plating and complete the gap.

On the SP line I removed 4 ties and replaced them with the Gapmaster, then sawed through the rails.

I had already used the Gapmaster with very good results on the double crossovers at Wesso.

This photo shows one of those after the track was painted and ballast was applied. After the ties are painted they blend in with the rest of the ties.

Monday, January 16, 2017

Not all tempered hard board is created equally

Almost two years ago I picked up a 4 x 8 ft sheet of tempered hard board to use as fascia and lighting valances on the layout. I had never worked with it before and soon discovered what a great and versatile material it is. I posted about this in the February 2015 post Installing fascia on the staging yard.

It just so happens that one of the small scraps left had the sticker on it shown in this photo.

So off to Lowes I went and I found this. It was a darker brown color and smooth on both sides but was the same thickness and was clearly labeled "tempered" so I thought I would give it a try.

I quickly found out that my new purchase was not the same quality as the one I had bought before. This photo shows a 4 inch wide strip that snapped when I attempted to bend it to the same radius that I had bent the lighter color product. This happened with several attempts.

So while I shop for the better version of the tempered hard board, I will use this other version where I can on areas that don't need to bend much.

This photo shows both types used along the edge of the top of the helix and along the front of the Winneumcca section.

I had gotten that sheet of hard board at either Lowes or Home Depot. It is a lighter brown and smooth on one side and fuzzy on the other. I have used most of it up now and needed to get some more.

It just so happens that one of the small scraps left had the sticker on it shown in this photo.

So off to Lowes I went and I found this. It was a darker brown color and smooth on both sides but was the same thickness and was clearly labeled "tempered" so I thought I would give it a try.

I quickly found out that my new purchase was not the same quality as the one I had bought before. This photo shows a 4 inch wide strip that snapped when I attempted to bend it to the same radius that I had bent the lighter color product. This happened with several attempts.

So while I shop for the better version of the tempered hard board, I will use this other version where I can on areas that don't need to bend much.

This photo shows both types used along the edge of the top of the helix and along the front of the Winneumcca section.

Friday, January 13, 2017

Installing the photo backdrops

Within the past few days, all 24 feet of Backdrops Junction photo backdrop has been installed. These were four 6 foot sections.

I decided to trim the top border from my backdrops. The borders were not consistent in width and I felt it was just a cleaner look to have the blue edge of the backdrop sky bordering the slightly off white of the FRP.

To do the trimming I used a spare FRP section as a work surface and trimmed the border with a razor blade and straight edge.

As I mentioned in the last post, I had tested several adhesives with scarps cut from the borders of my backdrops. Of the 4 adhesives I tested the best result came from the Scotch photo mount spray adhesive.

It does not slide around to allow adjustment but the material can be pulled up within a few minutes without damage if adjustment is needed.

This was my technique for the mounting and aligning seams. I used small pieces of double stick tape to temporarily hold the backdrop while positioning it.

There is extra material on each end for overlap. Line up the sections so the photos match, then make a mark above the top and below the top.

Painters tape was placed along the top edge to both mark the alignment and to mask for any over spray of adhesive.

I used a piece of cardboard aligned with the marks ( highlighted ) to mask the area of the backdrop that I did not want the spray to get on.

A seam is slightly less noticeable from the direction of the top layer. This photo shows the same seam, the left layer on top of the right layer.

A little planing on where the seams are to be and which angle they are most likely to be viewed from can give a better overall result.

After one end of the backdrop was secured, the other end was rolled back and double stick tape removed. Then working about 18 inches at a time the adhesive was applied and backdrop rolled out aligning with the blue tape on top. I used a narrow paint roller with a new pad on it to press the backdrop material onto the FRP.

The backdrop had to have a section cut out on the bottom where it rounded the corner so the bench work could fit under it. This was expected and the FRP already had a notch cut in it.

Here is the view from the other end of the room.

Now that this much backdrop is finished, the Wesso and Gloconda sections can be mounted in place, some fascia can be installed, and track and wiring connections made on those sections.

I decided to trim the top border from my backdrops. The borders were not consistent in width and I felt it was just a cleaner look to have the blue edge of the backdrop sky bordering the slightly off white of the FRP.

To do the trimming I used a spare FRP section as a work surface and trimmed the border with a razor blade and straight edge.

As I mentioned in the last post, I had tested several adhesives with scarps cut from the borders of my backdrops. Of the 4 adhesives I tested the best result came from the Scotch photo mount spray adhesive.

It does not slide around to allow adjustment but the material can be pulled up within a few minutes without damage if adjustment is needed.

This was my technique for the mounting and aligning seams. I used small pieces of double stick tape to temporarily hold the backdrop while positioning it.

There is extra material on each end for overlap. Line up the sections so the photos match, then make a mark above the top and below the top.

Painters tape was placed along the top edge to both mark the alignment and to mask for any over spray of adhesive.

I used a piece of cardboard aligned with the marks ( highlighted ) to mask the area of the backdrop that I did not want the spray to get on.

A seam is slightly less noticeable from the direction of the top layer. This photo shows the same seam, the left layer on top of the right layer.

A little planing on where the seams are to be and which angle they are most likely to be viewed from can give a better overall result.

After one end of the backdrop was secured, the other end was rolled back and double stick tape removed. Then working about 18 inches at a time the adhesive was applied and backdrop rolled out aligning with the blue tape on top. I used a narrow paint roller with a new pad on it to press the backdrop material onto the FRP.

The backdrop had to have a section cut out on the bottom where it rounded the corner so the bench work could fit under it. This was expected and the FRP already had a notch cut in it.

Here is the view from the other end of the room.

Now that this much backdrop is finished, the Wesso and Gloconda sections can be mounted in place, some fascia can be installed, and track and wiring connections made on those sections.

Sunday, January 8, 2017

Little bits of progress here and there

Since New Years I have been doing a little work in different parts of the layout.

Test fitted the section of backdrop that will be behind the Wesso section of the layout. Trimmed the bottom a bit to fit around the higher bench work of Winnemucca seen here on the right side of the photo.

I took a few test photos of some locomotives on the track in front of this back drop to see how things looked and was quite happy with the results. Makes me want to get all 24 feet of the back drop I have installed soon.

There was a good sized border at the end of the back drop section behind Winnemucca that I trimmed off to test with different adhesives on a piece of the FRP. This back drop is vinyl and I wanted to know the adhesive I use would not adversely affect the material.

Here are the results so far:

3M Super 77 Spray - I had used this with very good results on a module. That backdrop was a different brand and material. Glad I tried it out on a scrap from this back drop first as the results were awful this time. As can be seen in the photo, the adhesive reacted with the vinyl backing of the backdrop causing bulges and wrinkles.

Elmers Glue-All - The common white glue that many of us use for cork road beds, track, and scenery. I had also used this before on a backdrop on an old layout with good results. That back drop was paper backed. This seems to work well with this Backdrop Junction back drop with no interaction with the material and any that oozed out on the edges cleaned up easily and left no stain.

Roberts Vinyl Tile Adhesive - This was left over from installing the floor in the train room. While it holds well and gives a guy a little time to work with, anything oozing out on the edges easily stains the back drop.

Also did some work finishing up the bridge abutments on the Golconda section and installed some cork road bed on both lines on the approaches to the bridges. Need to get to the hobby shop for some more .060 x .060 styrene strip to finish the concrete sectional bridge in the rear.

On this rainy Sunday afternoon put together the LED light panels that go under the Carlin section. This photo shows the bench work sitting upside down with one panel open and the other closed. These LED light panels will light the staging yard.

Test fitted the section of backdrop that will be behind the Wesso section of the layout. Trimmed the bottom a bit to fit around the higher bench work of Winnemucca seen here on the right side of the photo.

I took a few test photos of some locomotives on the track in front of this back drop to see how things looked and was quite happy with the results. Makes me want to get all 24 feet of the back drop I have installed soon.

Here are the results so far:

3M Super 77 Spray - I had used this with very good results on a module. That backdrop was a different brand and material. Glad I tried it out on a scrap from this back drop first as the results were awful this time. As can be seen in the photo, the adhesive reacted with the vinyl backing of the backdrop causing bulges and wrinkles.

Elmers Glue-All - The common white glue that many of us use for cork road beds, track, and scenery. I had also used this before on a backdrop on an old layout with good results. That back drop was paper backed. This seems to work well with this Backdrop Junction back drop with no interaction with the material and any that oozed out on the edges cleaned up easily and left no stain.

Roberts Vinyl Tile Adhesive - This was left over from installing the floor in the train room. While it holds well and gives a guy a little time to work with, anything oozing out on the edges easily stains the back drop.

Also did some work finishing up the bridge abutments on the Golconda section and installed some cork road bed on both lines on the approaches to the bridges. Need to get to the hobby shop for some more .060 x .060 styrene strip to finish the concrete sectional bridge in the rear.

Labels:

back drop,

bench work,

Carlin,

Golconda,

Wesso

Sunday, January 1, 2017

Cold weather work

While we generally have a mild winter compared to most areas of the US, the period around the Christmas and New Years holidays is usually the coldest time where I live in Northern California. The little space heater I have in the train room does a decent job of keeping the room at 60 degrees or higher until the overnight lows dip into the 30's.

During this time I turn my attention to the things that keep me moving and warm and keep the progress going on the layout. Recently I went to Lowes and purchased another 4 x 8 sheet of tempered hard board to use for fascia and lighting valances and also a sheet of Fiberglass Reinforced Plastic or FRP to use to mount the photographic back drops on.

Here is a view of the Wesso section after the fascia / lighting valance has been installed on the east end return loop above.

I got a coat of primer on it now and am thinking about what color I want to use for the fascia.

The FRP panel has been extended nearly down to the far corner of the room above the work bench. The test layout with the Kato Unitrack was moved to the shorter wall to make way for this. The lighting valance under the cabinets has also been extended but not quite as far.

This cold snap should not last too long and I'll then get back to things like scenery and decoder installs.

During this time I turn my attention to the things that keep me moving and warm and keep the progress going on the layout. Recently I went to Lowes and purchased another 4 x 8 sheet of tempered hard board to use for fascia and lighting valances and also a sheet of Fiberglass Reinforced Plastic or FRP to use to mount the photographic back drops on.

Here is a view of the Wesso section after the fascia / lighting valance has been installed on the east end return loop above.

I got a coat of primer on it now and am thinking about what color I want to use for the fascia.

The FRP panel has been extended nearly down to the far corner of the room above the work bench. The test layout with the Kato Unitrack was moved to the shorter wall to make way for this. The lighting valance under the cabinets has also been extended but not quite as far.

This cold snap should not last too long and I'll then get back to things like scenery and decoder installs.

Subscribe to:

Comments (Atom)