I have one of those lighted magnifying glasses that is mounted on a folding arm to my work bench. This is the kind that has a circular fluorescent bulb with the magnifying glass in the middle and a push button to start. The fluorescent bulb needed to be replaced, plus the starting circuit had been acting up for some time. As there was nothing wrong mechanically with the lamp, I started to think about how it could be converted to LED's.

First step was to remove the fluorescent bulb and the clips that hold it in place.

Well actually, the very first step was to UNPLUG the lamp from the wall.

The push button switch was also removed and Anderson Power pole connectors were installed on the wires that were left.

I made a ring from a scrap of Masonite that fit right in where the fluorescent bulb had been. The ring was spray painted glossy white so it would be more reflective.

The ring was able to accommodate 7 of the LED modules that I have been using for the layout lighting. A small block of wood was attached to have a handle to remove the assembly from the lamp.

Here is the back side the the ring assembly.

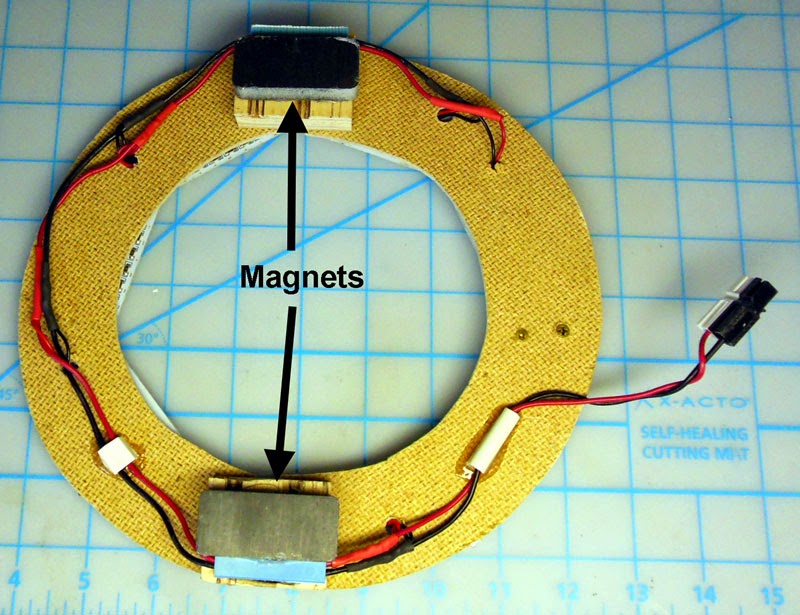

Magnets were attached to the back side with adhesive and all of the lighting modules were wired in parallel with an Anderson Power pole connector at the end of the chain.

Here is the completed ring installed in the lamp. The magnets are strong so just the two of them hold it in place. The handle was first put on to help remove the ring but it was also helpful in getting the ring into the right position.

The base of the lamp had a small box that contained the ballast transformer and this is where the AC cord connected.

I removed the AC cord and transformer, then connected the output of one of the power supplies that are being used for the layout lighting. It's a bit of an over kill for the 7 modules. The power supply was then mounted to the base of the lamp with adhesive.

The push button that had been removed was replaced with a simple ON / OFF toggle switch.

As can be seen in this photo the 7 LED modules provide plenty of light, I would say at least as much as the fluorescent bulb did.

In this view I think it looks a bit like an alien space ship.

Sunday, May 10, 2015

Sunday, May 3, 2015

Experimenting with reverse loops

The design of this layout includes 2 reverse loops to turn trains around in the staging yard at the west end of the layout. For those not familiar with reverse loops, here is a LINK to an article that explains it well. As I am moving along on the staging yard I realized that I have had very limited experience working with reverse loops. I decided to use my already existing temporary layout that is on a shelf above my work bench to get that needed experience. The layout uses Kato Unitrack so the changes would be easy.

There are several products available to work with a DCC system that handle the polarity switching that has to take place.

As I had already worked with DCC Specialties PSX-1 circuit breakers and have been quite happy with them, I decided to order their PSX-AR reverse loop circuit breaker to experiment with. This products senses the short that occurs and does the switching before the short gets to the DCC system.

I thought the simplest way to make a reverse loop would be to put a crossover in the middle of the loop. But as I soon found out, this is actually two reverse loops and my test engine would stall when crossing the gaps.

Realizing that as long as there was a standard non reversing section in the middle, both reverse loops could be connected to the same PSX-AR. So the next configuration was a double crossover as shown in the drawing below. What I really liked about his arrangement was that it is almost identical to what is at Wesso junction and will be modeled on the main layout.

In this configuration the single engine ran fine through any turnout configuration but when I started a second engine it caused the stalling problem whenever both reached gaps at the same time.

So next a second PSX-AR was added as shown in this drawing. Same test done with two engines running independently. This time no hesitation when both were crossing the gaps at the same time.

The existing temporary layout had consisted of an oval that used 11 inch radius curves. The layout shown in the drawings above used 9-3/4 inch radius curves and fit inside that existing layout. Then I added a double crossover connecting the two loops and also added a siding along the back of the outer loop so there ends up being quite a bit of track in the small space.

Here's a view of the central part of the modified temporary layout where all the turnouts are. Beyond this on either side is a double track balloon end. I've been running up to three short trains at a time to test everything. There can still be a stall if one engine is leaving a reverse loop section at the same time another engine is entering the same reverse loop section.

All three PSX circuit boards are mounted on a scrap of plywood on the wall under the layout to make it easier to see the status LED's on the boards. There is also a provision on these boards to connect remote LED's as well as many other features that I have not yet explored.

As I had already worked with DCC Specialties PSX-1 circuit breakers and have been quite happy with them, I decided to order their PSX-AR reverse loop circuit breaker to experiment with. This products senses the short that occurs and does the switching before the short gets to the DCC system.

I thought the simplest way to make a reverse loop would be to put a crossover in the middle of the loop. But as I soon found out, this is actually two reverse loops and my test engine would stall when crossing the gaps.

Realizing that as long as there was a standard non reversing section in the middle, both reverse loops could be connected to the same PSX-AR. So the next configuration was a double crossover as shown in the drawing below. What I really liked about his arrangement was that it is almost identical to what is at Wesso junction and will be modeled on the main layout.

In this configuration the single engine ran fine through any turnout configuration but when I started a second engine it caused the stalling problem whenever both reached gaps at the same time.

So next a second PSX-AR was added as shown in this drawing. Same test done with two engines running independently. This time no hesitation when both were crossing the gaps at the same time.

The existing temporary layout had consisted of an oval that used 11 inch radius curves. The layout shown in the drawings above used 9-3/4 inch radius curves and fit inside that existing layout. Then I added a double crossover connecting the two loops and also added a siding along the back of the outer loop so there ends up being quite a bit of track in the small space.

All three PSX circuit boards are mounted on a scrap of plywood on the wall under the layout to make it easier to see the status LED's on the boards. There is also a provision on these boards to connect remote LED's as well as many other features that I have not yet explored.

Subscribe to:

Posts (Atom)