Here is the collection of brass materials I found at my local hobby shop, Amazon, and ebay.

As you can see in the photo, I completed the painting on the yard since the last post.

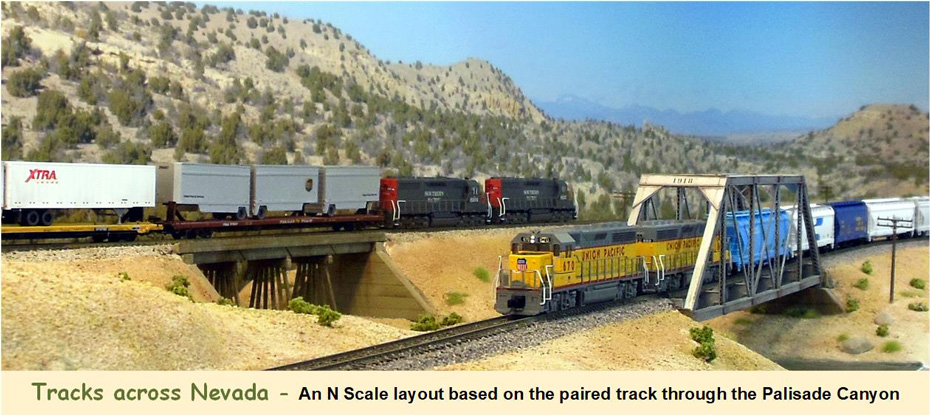

Here is the completed bridge in place along with it's Masonite deck. With the lower level cork in place it is clear to see how the two tracks cross each other. This cork on the lower level is the first to be installed anywhere on the layout. After I get the track put in on the lower level return loop, cork and track can then be installed on the upper level.

Here is a low angle view showing how the lower level track passes through the supports for the upper level track. Also seen is the Masonite deck of the upper level supported by the brass strips.